GRP Pipes are Revolutionary for Mining World!

Composite materials are usually labeled as revolutionary stuff among general people. However, industrial professionals are well informed about these materials and use them for producing GRP pipes, FRP components, and other composite products. GRP composites are available in the market since 50 years, but the modern world is getting to know about it later.

As GRP composite is an industrial stuff, it is mainly used for its excellent resistance to chemicals and acids and most types of corrosion. Along with these properties, there are more features offered by composite materials-

- Low cost

- Low mass

- Unique manufacturing and processing possibilities

- Customizable

- Easy to manufacture complex designs

- Low tooling costs

- Applicable to larger and small products

- Offer great surface finish

Why mining and metallurgy industry need composite materials?

We don’t know much, but here are some uses known to the experts –

- Chemical resistant piping

- Acid and chemical resistant tanks for platinum refining

- Ventilation ducting

- Insulation cladding for chilled water transport

Coal mining industry using composite pipes for the following things-

- Fresh water

- Acid water

- Slurries

GRP has become best alternative to steel and timber, which were inefficient to handle corrosion related to sulfuric acid. Today, coal and carbon fuel industry is using GRP composite material for all these good reasons.

More industries are using GRP ducting and pumps widely in corrosive applications, such as –

- Piping for chilled water will require lesser insulation

- Low mass and high capacity breathing apparatus cylinders

- Corrosion resistant air handling equipment

- Ventilation ducting

- Hydro power piping

- Slurry transport

- Corrosion resistant cable trays and gratings

- Air actuators

- Blast protection

- Water hydraulics

- Thermal insulation cladding

Benefits of using GRP composite systems –

- There is no need of insulation

- The piping is inherently corrosion resistant

- The piping have a low mass

- The piping can be installed easily

- The piping can be transported underground

- The piping has smaller cross section that makes it less space-consumer

- The piping has excellent surface finish

GRP composites can play more significant role in the local mining industry. The best performance of the material can be achieved if the GRP industry is willing to take risks, innovate, and make investment in technology and equipment. For now, GRP pipes are the best to bet for mining industry.

How to Avoid Internal Corrosion with GRP Products?

Every year, government spends millions on the maintenance of hydrocarbon pipelines to avoid breakdowns that is usually caused by internal corrosion. But now, with the help of latest techniques and technologies, GRP profiles manufacturers bring several products like GRP pipes in India. These profiles are economically attractive and anti-corrosive in nature. All these material options are being explored by operating companies to lower expenditures for pipeline maintenance activities and this lowers the chances of breakdown and ensures hassle free operations. In this article, we bring the salient features of GRPs along with their benefits and limitations as pipeline material of construction in the industries like oil and gas.

GRPs - The Material Mascot

GRP is a resin plastic that combines fiber and belongs to polymer category. It is commonly known as FRP or fiberglass reinforced plastic. A GRP pipe is a tubular product that contains glass fiber reinforcements embedded in or surrounded by cured thermosetting resin.

Manufacturers of GRP profiles use several varieties of resins and fiber reinforcement materials to fabricate GRP line pipes. Glass fiber material is supreme quality material used in over 90% of all filament or resin GRP manufacturing today. The resins are of different grades and types- polyester resin, vinyl ester resins, phenolic resins, and epoxy resins. Major salient features are:

- Superb corrosion resistance: GRPs are practically immune and resistant to every chemicals (almost) and other fluids used by oil and gas industry, the superb anti-corrosion property of the GRPs to all kinds of hydrocarbon fluids makes it popular materials of construction in gas and oil industry.

- Great strength and light weight: GRP materials are good at mechanical strength and can withstand moderate to extreme pressures during operation. The high strength of GRP pipes make the products easy to handle, easy to transport and installation. Moreover, manufacturers can select resin and fiber accordingly to maximize the service performance.

- Flexibility: The most advantageous thing of GRP is the flexibility it offers. Manufacturers can design numerous profiles in distinct sizes, lengths, and configuration to meet the standards and demands of the customer.

As GRP is anti-corrosive, gas and oil industry use GRP pipes for gases like CO2, H2S, and for salts and chlorides. Practically, GRP material is maintenance free. But, complete ignorance can bring certain maintenance issues.

GRP is still best material and most manufacturers of GRP pipes in India are happy to serve their services and products to the global clients. You can get these profiles from leading manufacturers like Fiber Tech.

How FRP Pipes Manufacturers Deal with Environmental?

Since manufacturing of FRP involves use of huge plants and furnaces, experts bring some environmental regulations for FRP manufacturers that may impact their business. In this post, you will read about these regulations and how manufacturers deal with them.

Air quality

Since manufacturers use styrene in most production methods for FRP manufacturing, it causes hazardous air pollution that makes it difficult for life to breathe at excessive levels.

Solution: The gelcoats containing less styrene can be used instead to emit less air pollution.

Experts issue permits to handle the amount of pollution that exhales into air by the factory plants. If the manufacturers use an average of 40 gallons of resin and gelcoat together in a day, they will need an air permit.

Water quality

Wastewater and polluted runoff affect the river and groundwater. Due to such pollution, potable water becomes unsafe for use, pollutants kill the marine life, and water bodies become unfit for swimming as well.

Is a permit needed for manufacturers for water quality?

Yes, water quality permit is a must for manufacturers if wastewater or wash water release to dry wells, surface water, or storm drains. They need to check with the sewage treatment plant prior discharging to the sewer. This is necessary for process water.

Industries need a storm water permit if manufacturing materials are exposed to storm water and the runoff enters a point source discharge like a ditch or storm drain.

Other than these, all drywells and sumps have to be registered and approved prior to use via underground injection control program.

Land quality

When manufacturers make use of solvents, it can generate dangerous waste that can degrade environment if not properly managed. The only solution to this is that they should create useful products to prevent formation of hazardous waste.

The regulations of hazardous waste include labeling, record keeping, and handling requirements.

How to manage this hazardous waste?

Remember that specific requirements rely on the status of quantity produced. Manufacturers must:

- Determine if the produced waste is hazardous

- Learn how to measure it

- Measure the waste to know the generator status

- Keep hazardous waste in closed containers

- Label and date your waste containers

- Meet storage time limit restrictions

In this way, FRP Pipes Manufacturers deal with environmental regulations to produce minimum pollution and make environment friendly for life.

FRP Gratings Manufacturers Making GRP and FRP Materials in House

Glass fiber reinforced plastics, GRP or FRP is a significant component used by FRP gratings manufacturers to intend distinct grating models. FRP material is applied for many reasons like- high mechanical strength, corrosion resistance, light weight, temperature resistance, and other properties. These materials have smooth internal surface, easy to form complex shapes, easy to repair and are thermal insulating and cost effective.

FRP or GRP materials have thermosetting resins and glass fiber. With regard to composing these ingredients and making the best resin choice, winding techniques and glass fiber components to ensure quality of the material, FRP grating manufacturing companies can be your ideal partner.

How manufacturers produce thermosetting product?

Designing a thermosetting product needs a chemical reaction in which molecules are created and energy is released. Once the new network of molecules exists, it gets the final shape. With this network of molecules, manufacturers get assurance for fire resistance feature, which means when material is heated, it will not catch fire. Thermosetting materials are epoxy, polyester, and polyurethane resins.

Manufacturing companies use glass fiber to enhance the mechanical strength, resistance to damage, and to sustain the original shape of the product. FRP material is used in the industry in wide array of shapes- roving, mats, glass veil, chopped strands, and bands. Experts pick the right composition of glass fiber and are able to apply, laminate and work this material to ensure extreme mechanical strength of the product.

At times, they also use other fibers in the products, like carbon.

FRP grating is glass reinforced plastic grating or fiberglass grating that possesses several advantages. Unlike traditional materials like steel, FRP doesn’t corrode or rust. This is the single reason that you often see FRP profiles around saltwater for docks, walkways, and hand rails.

Though in appearance, FRP gratings look like steel, but these are lighter in weight and durable than steel.

Companies in distinct industries have initiated the use of FRP gratings as these products are safer to use and have longer life cycle unlike traditional gratings and flooring materials. When you consider FRP grating service and prices, you should know some key facts about the products-

- FRP is resistant to rotting, warping, and decay that happen due to moisture and water exposure most of the time. Insects and bugs are also less able to damage the surface of FRP grating unlike timber products.

- FRP or fiberglass reinforced plastic grating is rust resistant. This feature is not available in steel gratings. FRP products do not dent under low impact situations, but aluminum often does.

- Since FRP is bad conductor of electricity, installers can avail safety by applying FRP gratings and flooring solutions at their site. The material is also non-sparking that lowers the risk of electrical shock.

To find latest offers and schemes related to FRP gratings, search for online FRP gratings manufacturers. You can tell them about your requirements with appropriate details and get a relevant quote from the experts.

Steps Involved in Cleaning of FRP Storage Tanks

It is not hard to clean FRP storage tanks if you have stored dry materials inside. But if you have stored any fluid/ chemical or even water, you need to perform several steps to clean it. If you are using storage tank for storing water, you should follow these steps shared in this post.

Most people give priority to water purification that they use as potable water. But they forget to pay attention on the storage tank cleaning where water is stored. Every day people use the water of the tank for personal hygiene, cleaning, moping, washing cloths and performing other household jobs. Over time, scale, sediments, and algae get deposited on the walls and surface of the tank that contaminate the water and make it unfit for use.

The presence of algae helps bacteria to grow and breed in the water, infects it and could make you sick eventually. You must clean your storage water tank at least once a year. However, cleaning routine is entirely depends on the quality of water supplied into homes. If the water is high in TDS and very hard, then you need to clean the tank more often. In such cases, user has to clean the tank more than one time in a year.

Steps involved in cleaning of storage tanks:

- The area surrounding the tank and tank top is cleaned

- Tools should be disinfected before using them for cleaning the tank

- Water and sludge is drained out from storage tank with the help of a sludge pump

- You should perform manual scrubbing to remove the sediments, dirt, fungus, and stains

- Walls, floor surface, and ceiling of the tank should be washed with a high pressure jet

- Perform vacuum cleaning to remove all the dirt with suction

- After performing vacuum cleaning, disinfect the tank with anti-bacterial spray or liquid bleach

- Fill the tank with water and let the water run through the taps to disinfect the water pipes as well

- Once the water is drained from the tank, leave the tank for drying

- Your storage tank is clean and ready to fill with water once again.

- You can store the water and use it for domestic tasks

Cleaning of FRP storage tanks takes 4-6 hours, but it is worth for the family health. You can perform these steps and ensure proper cleaning of your storage tanks.

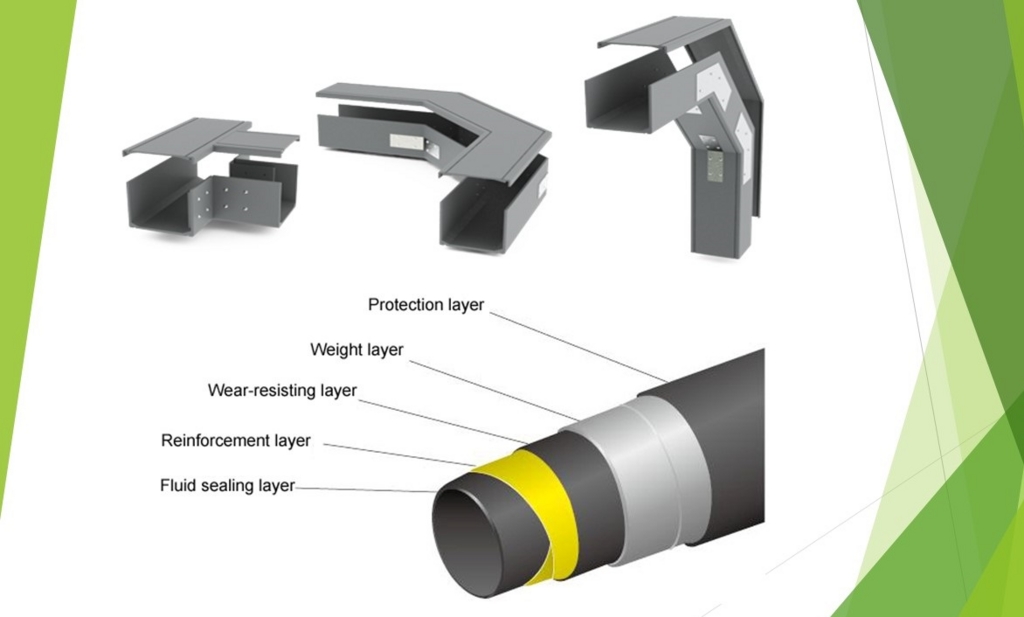

GRP Cable Trays Suppliers Describing Dry Wrap Reinforced Thermoplastic Pipe

FRP and GRP cable trays suppliers know the potential of composite pipeline technology to reduce installation expenses and enhance reliability for hydrogen pipelines. FRP is an existing commercially used technology presently employed in the oil and gas industry, chemical industry, food industry, etc. You get many benefits for using FRP and GRP products such as low installation cost, custom lengths and widths of the products, non-susceptibility of FRP to hydrogen embrittlement, corrosion resistance, chemical resistance, and more.

Manufacturers of GRP products evaluate their entire range through independent testing methods. They define changes to their present GRP product standards to meet the ASME code methodology. They build a data structure to support codification in the ASME Hydrogen Piping Code.

How manufacturers accomplish FRP products earlier?

Manufacturers perform several tests and evaluation methods to accomplish their FRP range of products prior years.

- They review the relevant FRP piping and pressure vessel standards completely.

- They tested FRP following low and high Ph exposure and evaluated joints for leakage.

- They tested flawed and best piping to evaluate design margins.

- They evaluated flaws effect on fatigue life of FRP products

- They evaluated stress impact and more

Dry Wrap Reinforced Thermoplastic Pipe product

The structural layer of the dry wrap reinforced thermoplastic pipe has an even number of helically wound tapes. Manufacturers don’t use any thermosetting resin inside or between these layers. The dry wrap helps in making the piping into a compact shape. Engineers then apply high strength axial pulling tapes to enable long continuous manufacturing and installation lengths.

How manufacturers perform leakage testing for thermoplastic pipe?

Manufacturing units follow two leak tests in the dry wrapped thermoplastic pipe samples. Another is by forming samples into a compact C shape and re-rounded before testing.

FRP and GRP products manufacturers are dealing in cable trays, gratings, piping and staircases across the world. They are doing many tests to evaluate different properties of their GRP profiles. They evaluate strength, durability, corrosion resistance, weathering, and deformation. If you need any GRP or FRP product for your infrastructure, ask manufacturers today.

You can avail GRP cable trays, GRP pultruded gratings, FRP cable trays, FRP profiles, and lots of related stuff. Ask in comments directly! Your views and feedback for his post will be appreciated by the experts. You can even influence readers to share this post with the world.

Manufacturers of FRP Pipes India Never Suggest Overlooking of Composites!

Even if your supplier says that you don’t have to maintain your FRP pipes India, ignore them. FRP materials are durable and require less maintenance is the true fact, but things do go wrong if you overlook them. You may have several reasons to replace your traditional pipe with FRP pipe. But engineers still want you to understand the nature and properties of the FRP that will help you in maintaining the piping system without making much effort.

The top feature of the FRP pipes is that these are inherently corrosion resistant because of the inert nature of the construction materials as compared to steel and CI materials. Manufacturers can easily design FRP pipe to meet 20-50 year code requirements. FRP materials are corrosion resistant and do not react to several acids and chemicals.

Lightweight construction is also a major benefit. Typical FRP pipe product is 75% lighter than the steel pipe and 90% lighter than the concrete pipe. Thus, the cost of shipping, handling, and installation of FRP pipe is comparatively less than the conventional materials.

The fatigue endurance and the strength-to-weight ratio of the material FRP are major attributes linked to the replacement costs and the ability to intend high performing, lightweight pipe systems.

Usual FRP pipe doesn’t conduct electricity, and has better electrical properties when compared with its steel counterparts.

Manufacturers can fabricate distinct sizes of FRP pipes in complex shapes. This is possible because FRP is a composite material that is adaptable to numerous manufacturing and tooling concepts.

Low cost maintenance is another feature that makes FRP pipes most preferred choice. Since FRP composites do not undergo the corrosive attack, they are easy to maintain. But a little care and cleaning is always needed to sustain its vibrant looks.

Materials of construction

Manufacturers of FRP pipes are using fiberglass reinforced thermoset resin, liner veil materials, and other additives. These materials are robust and make FRP pipes so durable and long lasting. These materials make the FRP pipes fire retardant.

Why it is still important to take care of your FRP pipes?

Since FRP materials are maintenance free, often users assume that they will never have to look after the FRP pipes. This is wrong because even if the pipes made with FRP materials are durable, they still require some attention. You have to clean them to get the shiny surface back.

This is why major manufacturers of FRP pipes India ask their customers to follow guidelines that are important for maintaining the FRP products.